Maintenance Scheduling

Optimize Your Maintenance Operations with Smart Scheduling Tools

Stay ahead of equipment failures and reduce downtime with ioX-CMMS’s Maintenance Scheduling module. Our intuitive tools make it easy to plan, automate, and manage maintenance tasks, ensuring your assets remain in peak condition. From routine preventive maintenance to complex scheduling needs, ioX-CMMS helps you keep operations running smoothly.

Optimize Uptime with ioX-CMMS: Streamlined Maintenance Scheduling for Equipment Reliability

ioX-CMMS’s Maintenance Scheduling module helps prevent equipment failures and minimize downtime by simplifying maintenance planning and management.

- Automated Scheduling

- Calendar View

- Customizable Maintenance Plans

- Integration with IoT Sensors

- Email/Text Notifications

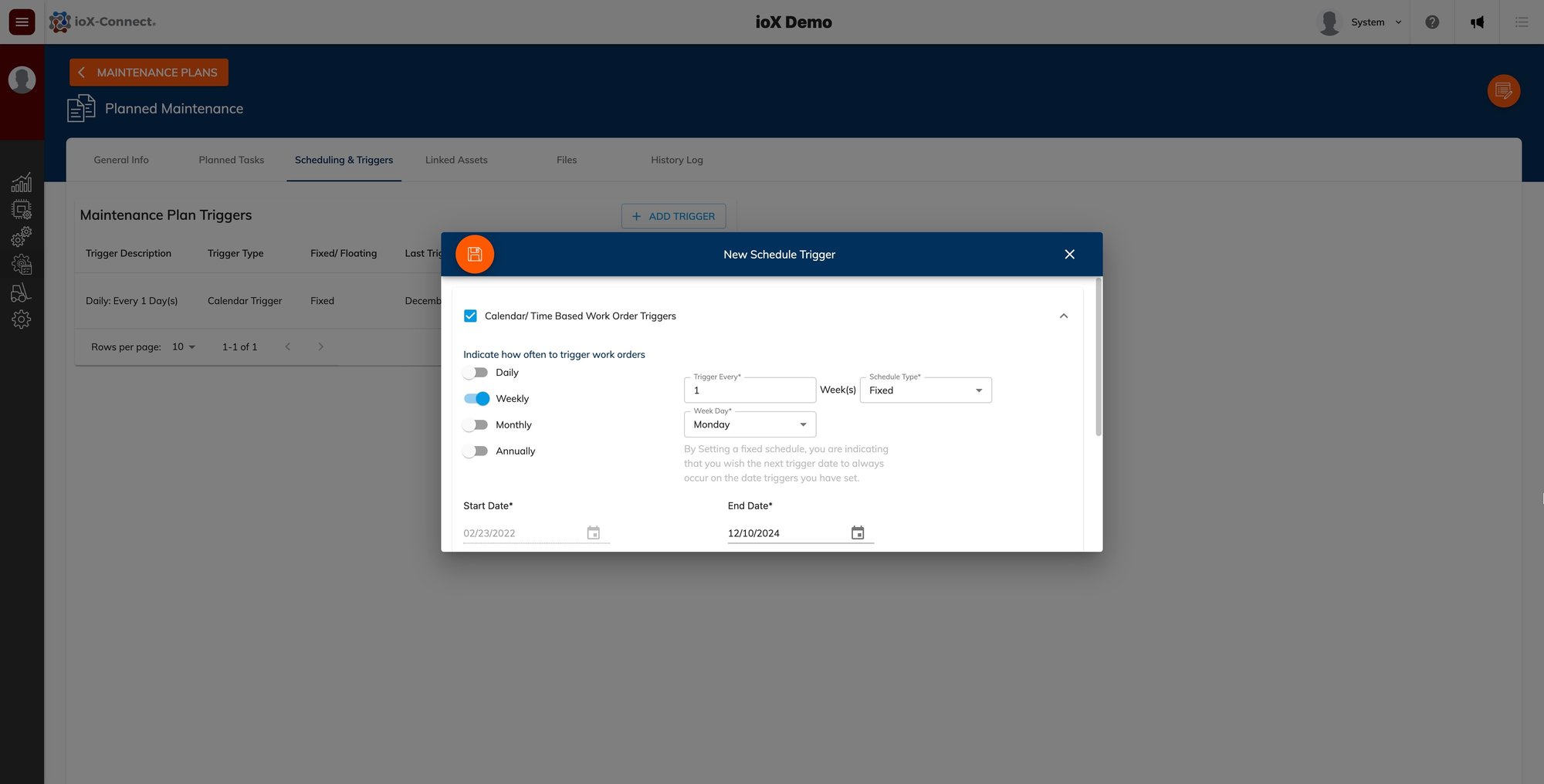

Automated Scheduling

Automate your maintenance processes to ensure tasks are never missed. With ioX-CMMS, you can set up recurring maintenance tasks based on time, usage, or condition triggers, allowing your team to focus on higher-value work.

- Set up recurring maintenance tasks based on time, usage, or condition triggers.

- Eliminate guesswork and manual planning with automated scheduling features.

- Configure multiple triggers for a single maintenance plan, such as a monthly schedule and a meter/hours-based trigger. Whichever condition is met first will trigger the maintenance task, ensuring timely execution.

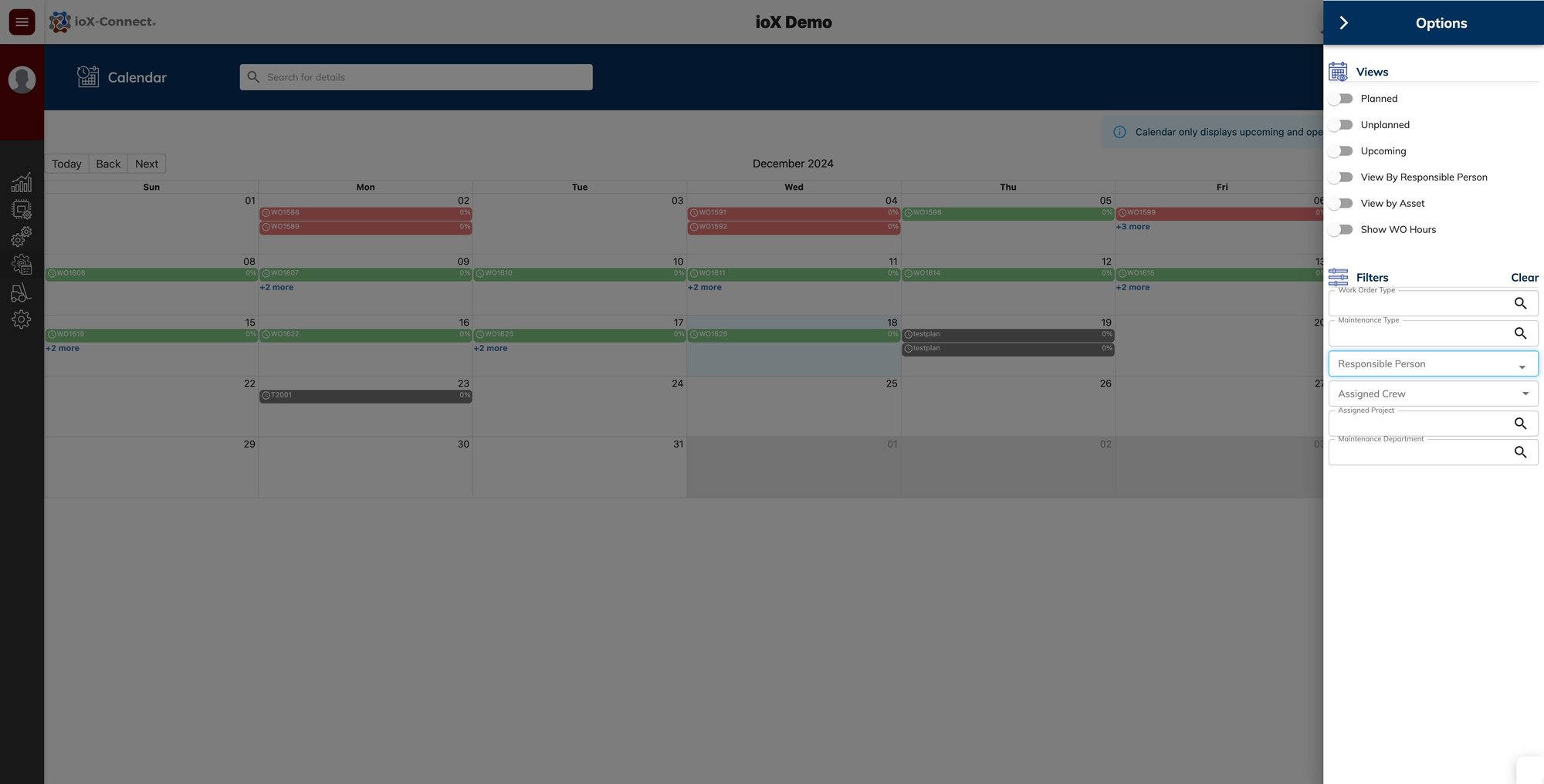

Calendar View

Gain a clear, visual overview of your maintenance schedule. The intuitive calendar view allows you to see upcoming tasks at a glance and make quick adjustments with drag-and-drop functionality.

- Visualize your entire maintenance plan in one place.

- Easily manage schedules with drag-and-drop calendar functionality.

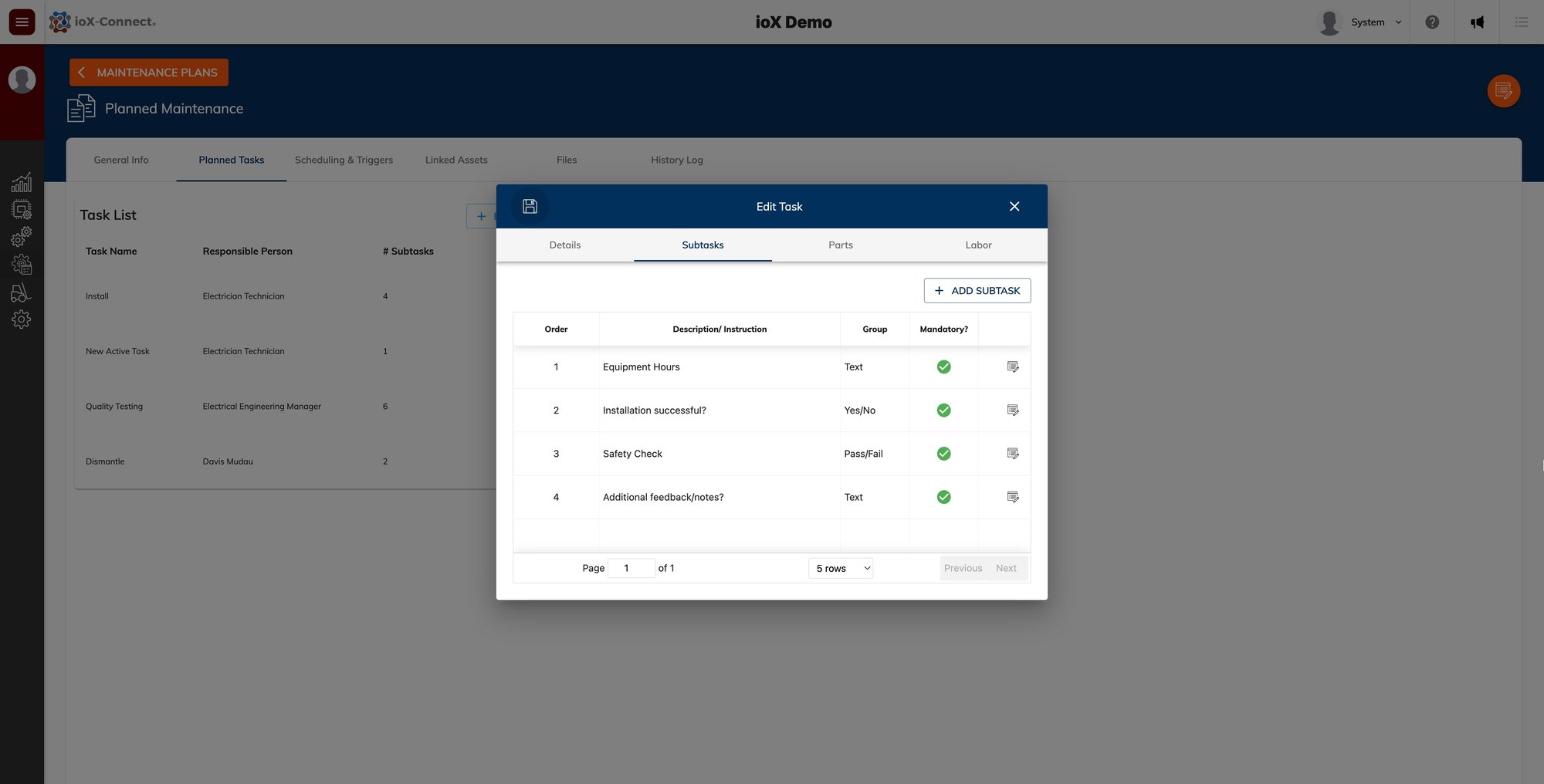

Customizable Maintenance Plans

Tailor maintenance schedules to fit your specific operational needs. ioX-CMMS allows you to create detailed plans with custom frequencies, tasks, and checklists, ensuring your maintenance strategy aligns with your workflow.

- Create maintenance schedules that fit your unique operations.

- Define frequencies, tasks, and checklists to match your workflow.

Built-in IoT Module

Leverage real-time data to optimize your maintenance schedules. ioX-CMMS integrates with ioX-Connect sensors, enabling automated maintenance triggers based on asset conditions, ensuring timely and efficient maintenance.

- Automate maintenance triggers with real-time data.

- Connect with ioX-Connect sensors to schedule maintenance based on asset conditions.

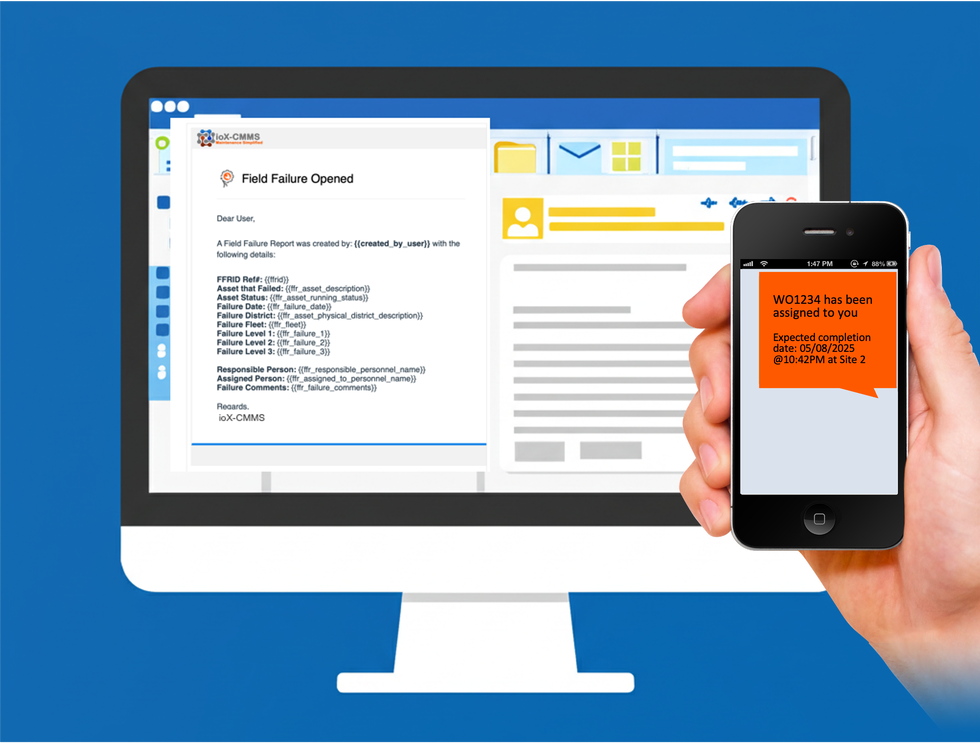

Instant Notifications: Stay in the Loop

Keep your team in sync with automatic email and text message alerts. As soon as a maintenance task is assigned or its status changes, technicians receive real-time notifications—no more missed work orders or waiting for updates.

- Ensure everyone is informed of new assignments or changes to ongoing tasks.

- Reduce lag time and miscommunication with instant alerts sent directly to your maintenance staff’s inbox or mobile device.

- Help your team respond faster to high-priority maintenance needs by delivering updates wherever they are.

Whether your technicians are on-site or in the field, these alerts help streamline communication so nothing slips through the cracks.

Major Fracking Company

VP Maintenance Management

"ioX-CMMS is a game-changer in the maintenance management industry. It has helped us reduce equipment downtime and optimize our manpower. Highly recommended!"

Pharmaceutical Manufacturer

Engineering Manager

"ioX-CMMS is a top-performing maintenance management solution in the market. Its innovative tools and exceptional service make it a must-have for any business."

Connected

Designed specifically for IoT and mobile applications. Integrates with sensors, meters, PLCs, SCADA, ERP, MES, and nearly all corporate systems and solutions.

Fast

ioX-CMMS is quick to implement and use, with tools enabling setup in days and work orders in hours or seconds.

Smart

Our Dashboards and Analytics excel, offering standard options for basic needs and Custom Analytics for complex requirements.

Mobile

Our iOS app enables field technicians to manage work tasks and record job details effortlessly, designed for ease of use even for beginners.

Trusted by customers across multiple industries

Frequently Asked Questions About CMMS and Preventative Maintenance

Have more questions about how a CMMS can transform your maintenance operations? We’re here to help! Explore our FAQs for quick answers to common questions, or feel free to reach out to our team for personalized assistance. Let us guide you toward the right solution for your business needs.

Preventive maintenance software is an essential component of maintenance management systems that enhances the efficiency and lifespan of equipment and facilities. Describing it as merely a tool understates its pivotal role in optimizing operations. This software orchestrates and automates the routine scheduling, prioritization, and tracking of maintenance tasks.

Key Benefits:

-

Centralized Information Hub: It consolidates all relevant data, encompassing assets, instruction manuals, inventory lists, and maintenance histories. This centralization minimizes the chaos typically associated with manual paperwork, offering a seamless data flow.

-

Streamlined Operations: By automating routine tasks and reminders, it prevents the oversight of crucial maintenance activities, reducing the risk of unexpected breakdowns and costly repairs.

-

Enhanced Communication: Facilitates clear communication among technicians and managers by providing real-time status updates and progress tracking.

Functionality Highlights:

-

Scheduling: Automatically generates maintenance schedules based on predefined criteria, ensuring tasks are conducted at optimal intervals.

-

Prioritization: Assesses and ranks tasks by urgency and importance, allowing teams to focus on the highest-impact operations first.

-

Reporting: Delivers comprehensive reports on maintenance history and performance trends, aiding in informed decision-making.

With a robust system in place, businesses can not only maintain but enhance their operational efficiency, ultimately contributing to a stronger bottom line. Whether in manufacturing, healthcare, or public services, implementing preventive maintenance software is a strategic move toward sustainable asset management.

Preventive maintenance software isn't just for one sector; its advantages span across numerous industries, enhancing operations and extending the lifespan of assets in various fields.

Manufacturing

For manufacturing companies, downtime can be costly. Implementing preventive maintenance software can significantly reduce unexpected equipment failures, keeping production lines running smoothly and efficiently. Regular maintenance schedules ensure machinery operates at full capacity, minimizing interruptions.

Healthcare

Hospitals and clinics rely on a plethora of medical devices and equipment. Preventive maintenance software helps in scheduling regular checks, ensuring all devices are in peak condition, thereby maintaining high standards of patient care and complying with safety regulations.

Hospitality

The hospitality industry, including hotels and resorts, benefits from preventive maintenance by maintaining guest satisfaction. Regular upkeep of amenities, HVAC systems, and kitchen equipment prevents breakdowns that could disrupt guest services.

Transportation and Logistics

For fleets in the transportation and logistics industry, operational vehicles are the backbone of business. Scheduling routine inspections and maintenance reduces breakdowns and extends vehicle longevity, ensuring timely deliveries and satisfied clients.

Utilities

Utilities companies, responsible for providing essential services like water, electricity, and gas, can reduce service interruptions with preventive maintenance. Regular inspections and servicing of infrastructure components help maintain steady and reliable service delivery.

Education

Educational institutions also find value in preventive maintenance software. Managing the upkeep of computer labs, HVAC systems, and campus facilities ensures a safe and conducive learning environment for students and faculty alike.

Overall, preventive maintenance software enhances efficiency and reduces downtime, empowering organizations across various sectors to proactively manage their assets. Whether it's in manufacturing, healthcare, or beyond, staying ahead of potential breakdowns saves time and money, ultimately improving service and product delivery.

Preventive maintenance software is a game-changer when it comes to minimizing unexpected costs and delays. By implementing this technology, you can ensure smoother operations and protect your bottom line. Here’s how:

Proactive Scheduling

Instead of dealing with sudden breakdowns, preventive maintenance software allows you to create a systematic approach to handle maintenance tasks. This proactive scheduling can help prevent expensive repairs that arise from neglected issues.

Real-Time Monitoring

Utilizing real-time data, the software provides insights into the condition of your assets. Whether it's vehicles, machinery, or electronic systems, identifying potential problems early means you can address them before they turn into significant, costly disruptions.

Efficient Resource Management

With preventive maintenance software, allocate resources efficiently. The program enables tracking of parts and labor, ensuring you have what you need on hand and avoiding unnecessary downtime waiting for supplies or personnel to be available.

Data-Driven Decisions

Leverage historical data for better forecasting. Predictive analytics can inform your maintenance schedule and budgeting decisions, helping you avoid over or under-maintaining assets, which both lead to wasted money.

Standardized Procedures

Implementing standardized maintenance procedures ensures consistency and quality in servicing your assets. This can reduce errors, prevent routine oversights, and ensure that every piece of equipment is in optimal condition.

Key Takeaways:

- Schedule Proactively: Prevent breakdowns before they occur.

- Monitor Actively: Use real-time data for timely interventions.

- Manage Resources Wisely: Optimize the use of parts and labor.

- Leverage Data: Make informed maintenance decisions.

- Standardize Processes: Achieve consistency across the board.

By integrating preventive maintenance software into your operations, you not only slash unexpected costs and delays but also foster a more reliable and efficient working environment.

Workload Balancing

Ensure efficient use of your maintenance team's time with intelligent workload balancing. ioX-CMMS provides easy-to-read employee summary reports, giving you a snapshot of the hours assigned to each technician across a given time period. This lets you spot gaps or overloads in individual schedules at a glance.

- Visualize each technician’s scheduled hours and current workload.

- Allocate tasks based on real-time availability to prevent overbooking or idle time.

- Distribute work evenly to optimize team productivity and keep maintenance operations flowing smoothly.

Absolutely, preventive maintenance is an effective strategy for reducing the need for reactive maintenance. By implementing a proactive approach, organizations can significantly decrease unexpected equipment failures and the associated costs.

Why Preventive Maintenance Makes Sense

-

Proactive Problem-Solving: Instead of waiting for machinery to break down, regular maintenance checks allow teams to anticipate and fix issues before they escalate.

-

Cost Efficiency: Scheduled maintenance minimizes sudden emergencies that often incur higher costs due to urgent repairs and expedited parts shipping.

-

Decreased Downtime: Preventive strategies lead to less unplanned downtime, ensuring operations run smoothly. This boosts productivity across all sectors, from manufacturing to healthcare.

-

Extended Asset Lifespan: Routine upkeep helps to extend the life of equipment, providing more value from technology and machinery investments over time.

Benefits Across Industries

All industries, regardless of size or function, benefit from adopting preventive maintenance practices. Facilities management in commercial real estate, for example, can see substantial reductions in operational disruptions. Similarly, automotive and aerospace sectors often leverage this approach to uphold high safety and reliability standards.

Preventive maintenance offers a decisive edge in staying ahead of potential breakdowns. It’s a strategic move not just for reducing reactive repairs but also for enhancing overall operational efficiency. By focusing on preventive care, organizations can save time, money, and resources, ultimately ensuring continuous and reliable service.

Understanding Cost and Labor Tracking in Preventive Maintenance Software

Preventive maintenance software streamlines the management of maintenance tasks by meticulously tracking costs and labor.

Here's how it functions:

-

Detailed Cost Recording: Users can log every expense associated with maintenance activities. This includes parts, tools, and other related costs. This ensures all financial aspects are captured accurately.

-

Time Management: The software allows you to monitor the time spent on each task. By recording labor hours, it provides a clear picture of the manpower utilized for maintenance activities.

-

Comprehensive Reporting: After data is entered, the software compiles it into summary reports. These reports highlight total expenses and labor hours, offering valuable insights into maintenance efficiency and budget management.

-

Data Insights: By analyzing these reports, decision-makers can identify cost-saving opportunities and optimize labor usage, thereby improving overall maintenance operations.

Through these features, preventive maintenance software not only improves accuracy in tracking but also aids strategic planning and resource allocation.

Preventive maintenance software plays a crucial role in minimizing liability risks for businesses across various industries. Here's how it makes a difference:

-

Comprehensive Record-Keeping: With preventive maintenance software, you maintain an accurate and detailed log of all maintenance activities. This documentation is crucial in demonstrating compliance with safety and industry regulations, helping you steer clear of potential legal trouble.

-

Proactive Issue Identification: The software enables regular inspections and checks, allowing you to address potential issues before they escalate into serious problems. Catching these issues early can prevent accidents and malfunctions that could result in liability claims.

-

Automated Scheduling: By automating maintenance schedules, the software ensures that no critical maintenance task is overlooked. Consistent upkeep reduces the likelihood of equipment failure, safeguarding both employees and customers from harm.

-

Compliance Assurance: It assists you in adhering to industry standards and legal requirements by keeping you updated on necessary inspections and certifications. Staying compliant minimizes the risk of fines or penalties associated with non-compliance.

-

Improved Equipment Longevity: Regular maintenance extends the lifespan of your equipment, reducing the chance of unexpected breakdowns. Well-functioning equipment decreases the risk of workplace accidents and the ensuing liability issues.

By harnessing the power of preventive maintenance software, businesses not only enhance their operational efficiency but also significantly reduce their liability exposure. Whether you're in manufacturing, healthcare, or facilities management, this tool is invaluable in maintaining a safe, compliant, and risk-averse environment.

Seamless Transition Made Simple

Switching to a preventive maintenance software platform might seem like a daunting task, but it's surprisingly straightforward. Begin by scheduling a demo to see the software in action and take advantage of a free trial period, which allows you to explore features without commitment.

Customized Setup Support

Worried about transferring your existing data? You aren't alone. Thankfully, the transition process involves expert assistance from ioX-Connect staff that have years of implementation experience. A dedicated team collaborates with your personnel to ensure smooth data migration and tailor workflows to suit your organization's unique needs.

User-Friendly Interface

One of the biggest hurdles in adopting new software is usability. Fortunately, ioX-CMMS was crafted with intuitive designs that require minimal training. This ensures that everyone in your team, from technical staff to casual users, can navigate the platform with ease and efficiency.

Ongoing Assistance and Support

Switching platforms isn't just about installing new software—it's about continuous support. ioX-CMMS offer comprehensive training sessions to get your team up to speed. Plus, we provide ongoing lifetime support to address any questions that may arise as you integrate the platform into daily operations.

By choosing the ioX-CMMS preventive maintenance software platform, the switch can be a relatively stress-free process, equipping your team with powerful tools for efficiency and success.

Absolutely, importing existing maintenance data into the ioX-CMMS preventive maintenance software platform is possible. Typically, this is done by exporting your data into an Excel file using a standardized format. Once you've got the data in the correct format, our team will assist you to effortlessly transfer it into ioX-CMMS.

Here's a step-by-step approach:

-

Export Data: Begin by exporting your current maintenance data into an Excel spreadsheet. Make sure to follow any formatting guidelines provided by your ioX-CMMS account manager or one of our technical support staff.

-

Use a Template: Utilize an Excel template approved by ioX-CMMS. This ensures the data aligns correctly upon import. In some cases we will use your exported data as is and do the data mapping for you.

-

Data Import: Upload the formatted Excel file into the ioX-CMMS preventive maintenance platform. The system will integrate the data, allowing you to keep track of historical maintenance information seamlessly.

By following these steps, you maintain data continuity and gain valuable insights for future maintenance planning.

Streamlined Project Tracking for Long-Term Initiatives

Managing long-term projects doesn’t have to be overwhelming. With ioX-CMMS, you can easily schedule and monitor ongoing projects by creating dedicated Project Work Orders within the maintenance scheduling system. These work orders provide a centralized space to log daily progress, including parts and labor, so your team can keep a close eye on each phase as it unfolds.

- Track daily activities and resource usage directly in the system.

- Access detailed reports showing progress over time—well before the final completion.

- Stay informed at every step without juggling multiple spreadsheets or paper logs.

With all your project data organized in one place, you’ll always have a clear picture of where things stand and can make timely, informed decisions to keep projects on schedule and within budget.

Preventive maintenance software offers a comprehensive solution for managing inventory supply efficiently. By integrating inventory management into your maintenance system, you gain a clear view of spare parts and consumables, ensuring that your stock levels are always optimal.

Key Features and Benefits

-

Real-Time Tracking: The ioX-CMMS software continuously monitors inventory levels, updating quantities in real-time. This feature helps prevent unexpected shortages and overstock situations, which could disrupt scheduled maintenance activities.

-

Automated Alerts: Set threshold limits for each item, and the system sends automated alerts when stock levels fall below these parameters. This proactive approach ensures timely reordering, reducing downtime and keeping operations running smoothly.

-

Centralized Database: All inventory data is stored in a centralized database, providing easy access to information on part usage, costs, and availability. This not only helps in making informed purchasing decisions but also in forecasting future needs.

Integration with Maintenance Schedules

-

Linking Parts to Tasks: By associating specific parts with maintenance tasks, the ioX-CMMS software can automatically adjust inventory levels as tasks are completed. This ensures that the right parts are available when needed, enhancing efficiency.

-

Historical Data Analysis: Analyze past data to predict future inventory demands. This helps in planning budget allocations and minimizing waste by purchasing only the necessary quantities.

Incorporating inventory supply management into your preventive maintenance framework streamlines operations, cuts costs, and ensures that your maintenance team always has the resources it needs. Balancing real-time data, automation, and historical insights, the system is tailored to optimize every aspect of inventory control.

Yes, ioX-CMMS can definitely accommodate various access levels for different users. By setting up distinct user roles, you can tailor permissions and visibility to fit your team's specific needs. This flexibility allows managers, technicians, and other staff to access only the features and information that are relevant to their roles.

Such customization ensures that sensitive data is protected while still providing easy access to necessary tools for each team member. Whether it's assigning maintenance tasks, viewing service schedules, or generating reports, you can configure user settings to streamline operations and enhance productivity.

A Computerized Maintenance Management System (CMMS) is software that helps organizations manage and streamline maintenance operations. It tracks work orders, schedules preventive maintenance, monitors assets, and provides analytics to improve efficiency and reduce downtime. For a more in depth look at what is a CMMS, check out our What is a CMMS Informational Page

A CMMS centralizes maintenance data, allowing users to create work orders, schedule tasks, track asset performance, and access real-time insights. Technicians can update task statuses, log maintenance activities, and access manuals or checklists, ensuring smooth operations.

A CMMS improves maintenance efficiency, reduces unplanned downtime, extends asset lifecycles, and enhances compliance. It also provides data-driven insights for better decision-making and streamlines communication between teams.

Additional Benefits of Preventive Maintenance Software

-

Minimize Unplanned Downtime: By scheduling regular maintenance, you can significantly cut down unexpected operational halts, ensuring a smoother workflow.

-

Increase Equipment Lifespans: Routine checks and maintenance extend the life of critical assets, saving costs on replacements and repairs.

-

Prevent Production Delays: Consistent attention to equipment health prevents hiccups in production schedules, allowing for timely project completion.

-

Lower Total Maintenance Costs: Prioritizing preventive measures leads to reduced emergency repairs and optimized resource allocation, which in turn reduces overall expenses.

-

Reduce Safety and Liability Risks: Regular maintenance ensures that all equipment operates safely, minimizing the potential for accidents and associated liabilities.

Integrating these benefits with the functionality of ioX-CMMS means you’re not just maintaining equipment but optimizing your entire maintenance strategy. With comprehensive data and streamlined communication, teams can work more cohesively, making informed decisions that bolster both productivity and safety.

CMMS software is used by maintenance managers, technicians, and facility managers across industries such as manufacturing, healthcare, hospitality, utilities, and logistics to manage equipment and facilities effectively.

While both systems manage assets, a CMMS focuses on maintenance operations, such as work orders and preventive maintenance. Enterprise Asset Management (EAM) provides broader asset lifecycle management, including procurement, inventory, and financials.

Yes, a CMMS like ioX-CMMS supports multi-site management, allowing users to track assets, work orders, and maintenance schedules across multiple facilities from a single platform, ensuring data segregation and efficient management.

A CMMS automates preventive maintenance scheduling based on time, usage, or condition triggers. This ensures timely inspections and repairs, reducing breakdowns and extending equipment lifespans.

Modern CMMS platforms, like ioX-CMMS, are designed with an intuitive interface, making them easy to use for technicians and managers alike. Mobile accessibility further enhances usability, allowing updates from anywhere.

A CMMS provides detailed reports on work order history, asset performance, maintenance costs, technician productivity, and compliance metrics. These insights help optimize maintenance strategies and improve ROI.

To choose the best CMMS, consider your organization's size, industry, and specific needs. Look for features like work order management, preventive maintenance, multi-site support, mobile access, and robust reporting. A scalable and customizable solution like ioX-CMMS is ideal for businesses of all sizes.

Our Products and Services?

We're here to help, do not hesitate to reach out to us by scheduling a quick call with one of our representatives.

Contact Us

Our customer service team is ready to assist you in exploring our offerings tailored to your business objectives.