CMMS Reporting & Analytics

Unlock Actionable Insights with Powerful Reporting & Analytics

Make data-driven decisions and optimize your maintenance operations with ioX-CMMS’s Reporting & Analytics module. Our powerful tools provide comprehensive insights into work orders, asset performance, inventory usage, and maintenance efficiency. Visualize key metrics, identify trends, and generate custom reports to ensure your maintenance strategy is always on point.

Enhance Maintenance with ioX-CMMS Reporting & Analytics Insights

Optimize maintenance with ioX-CMMS’s Reporting & Analytics, offering insights into work orders, asset performance, and efficiency.

- Customizable Reports

- Real-Time Dashboards

- Performance Analytics

- Asset Lifecycle Tracking

- Inventory Usage Reports

- Report Scheduling

Customizable Reports

Create tailored reports to meet your unique maintenance needs. ioX-CMMS allows you to generate reports on work orders, assets, inventory, and more, ensuring you get the exact insights you need.

- Build custom reports based on specific criteria.

- Filter, sort, and export data for deeper analysis.

- Schedule automatic report generation and distribution.

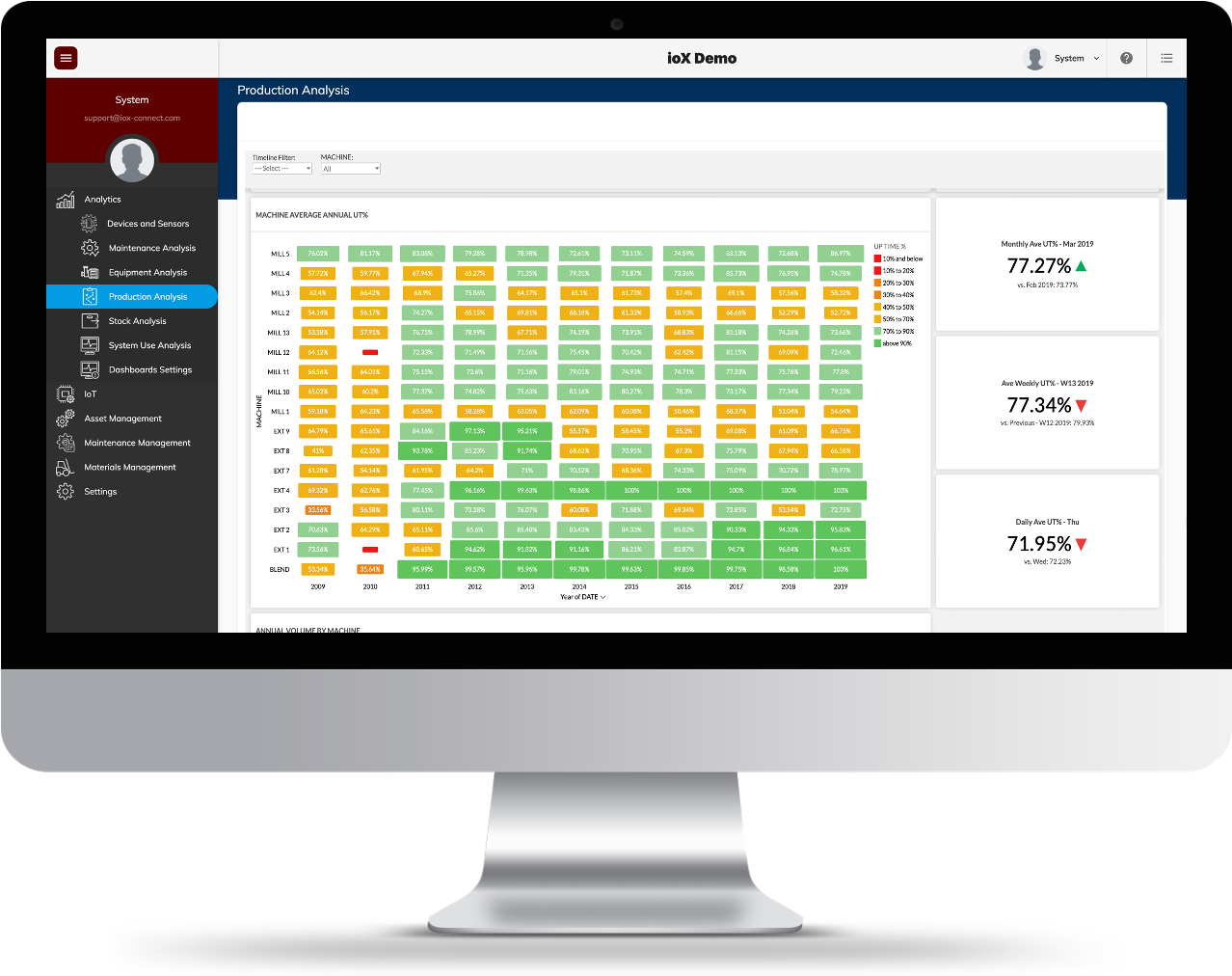

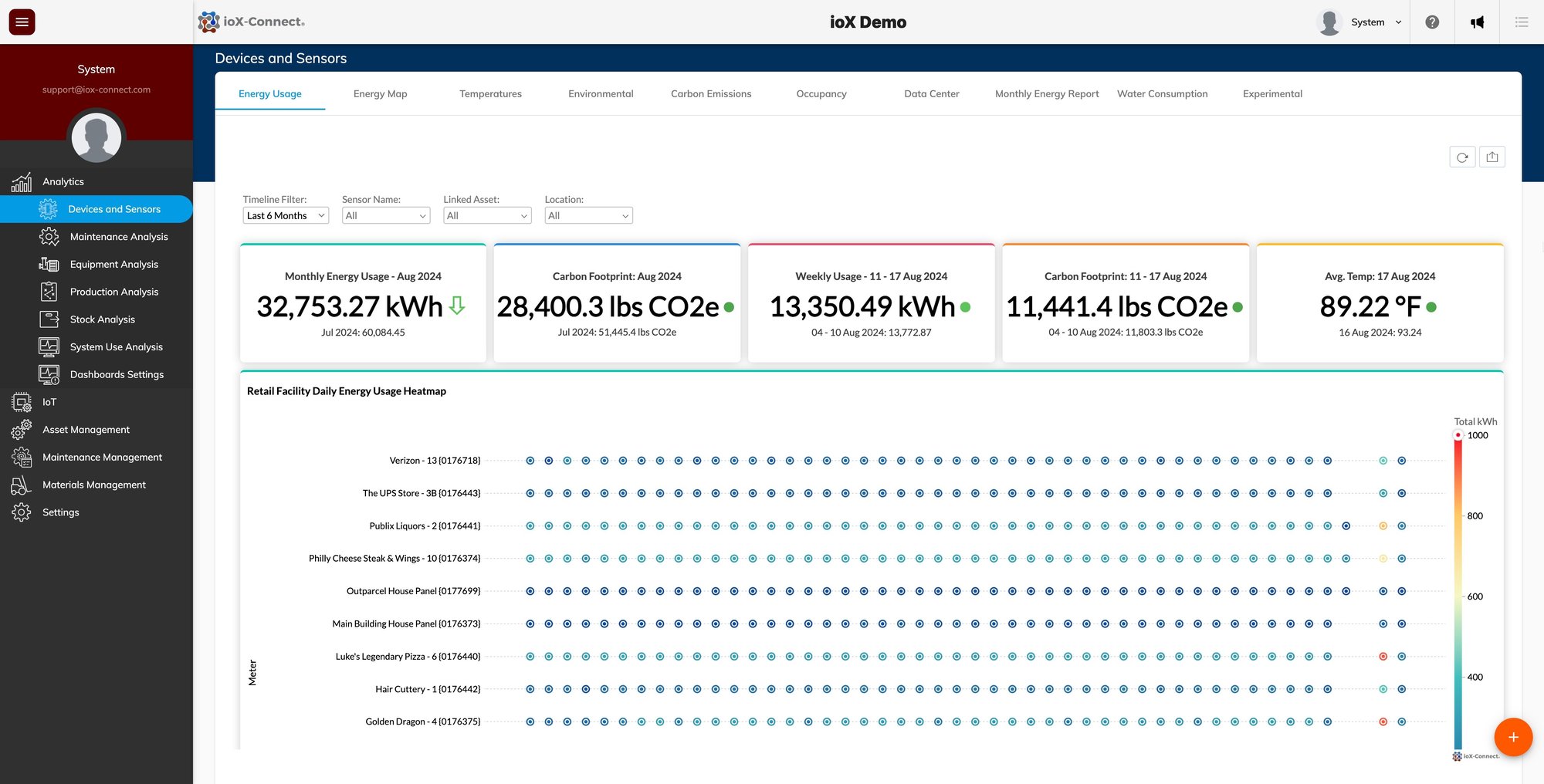

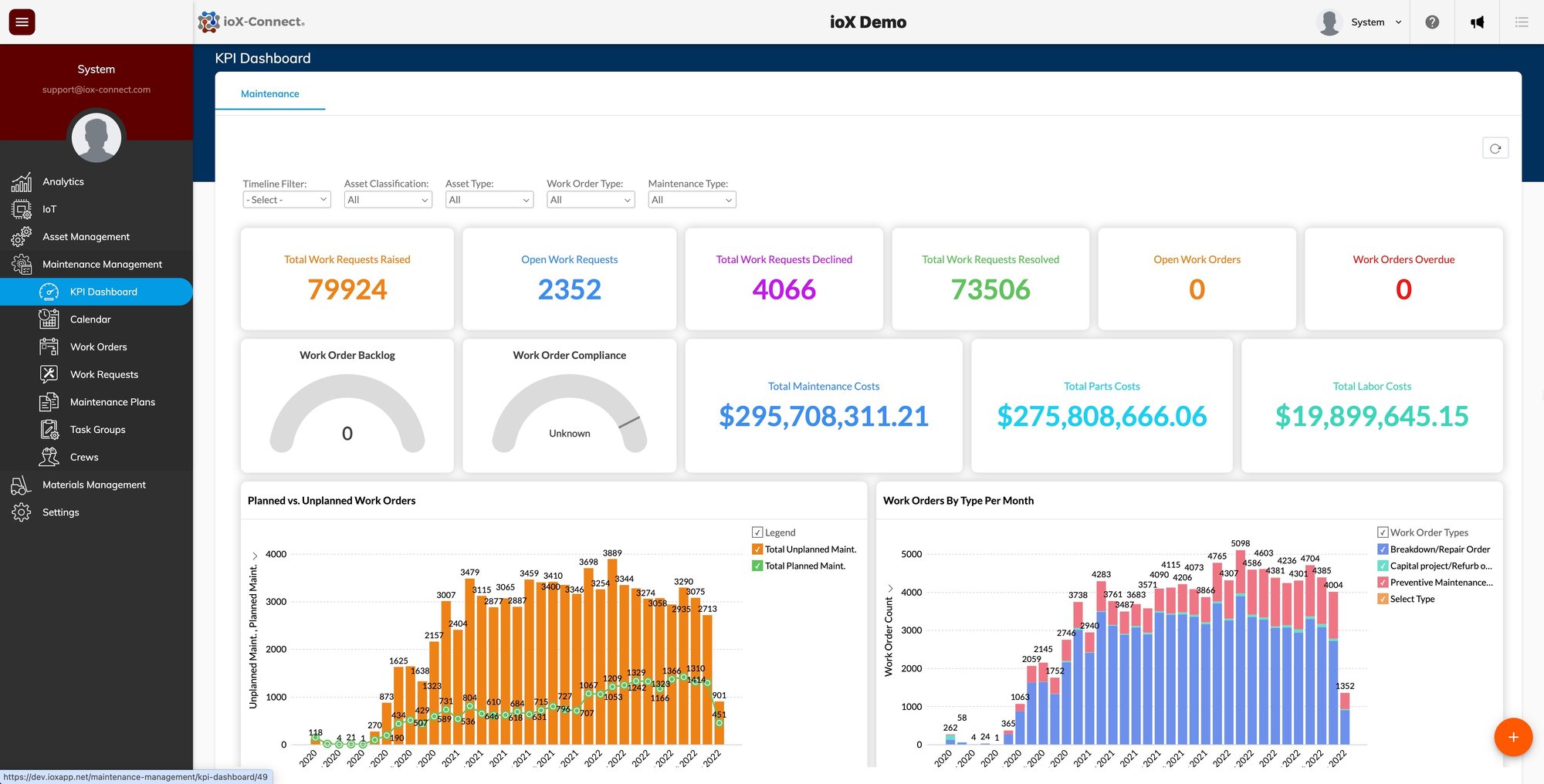

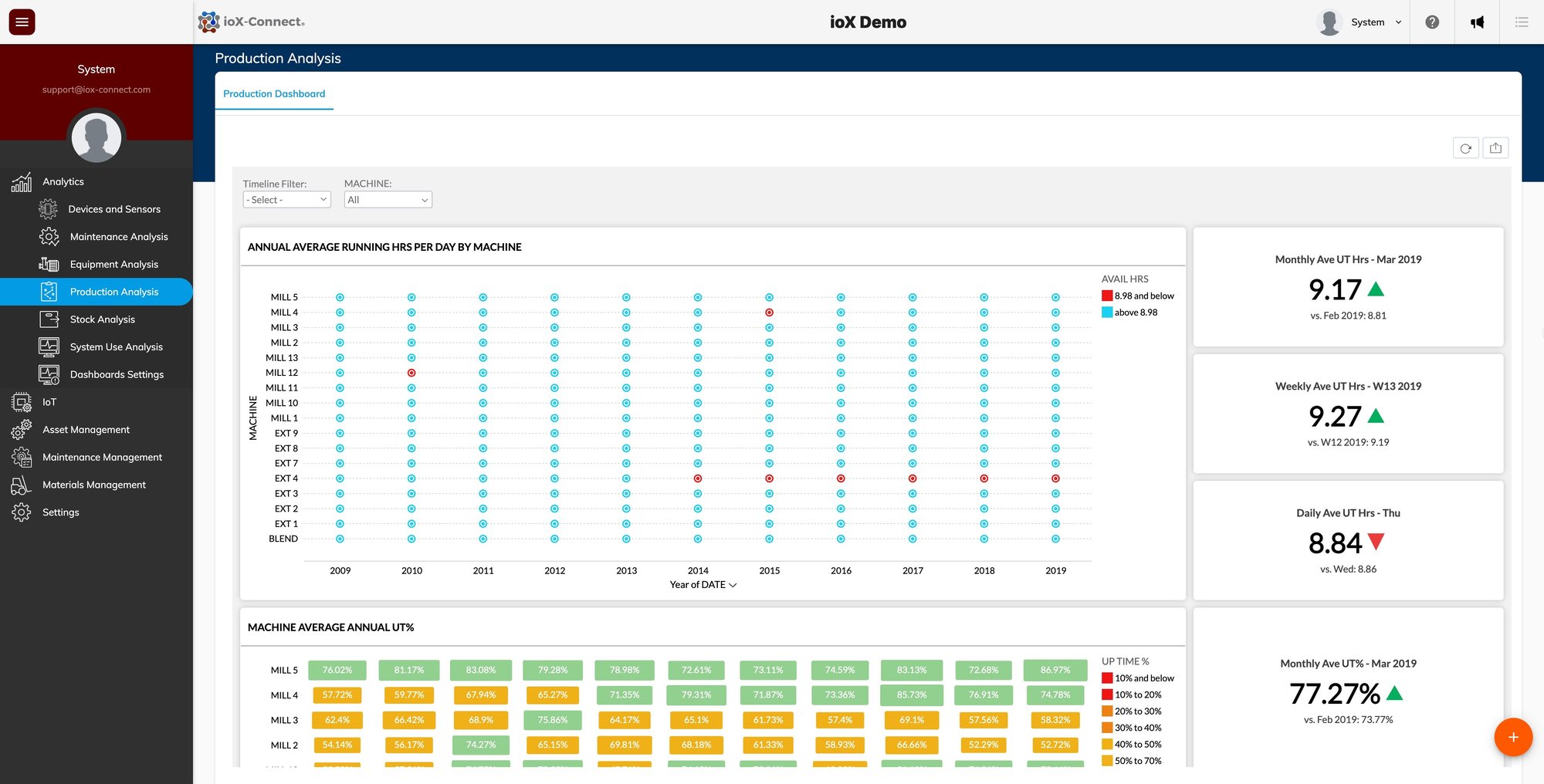

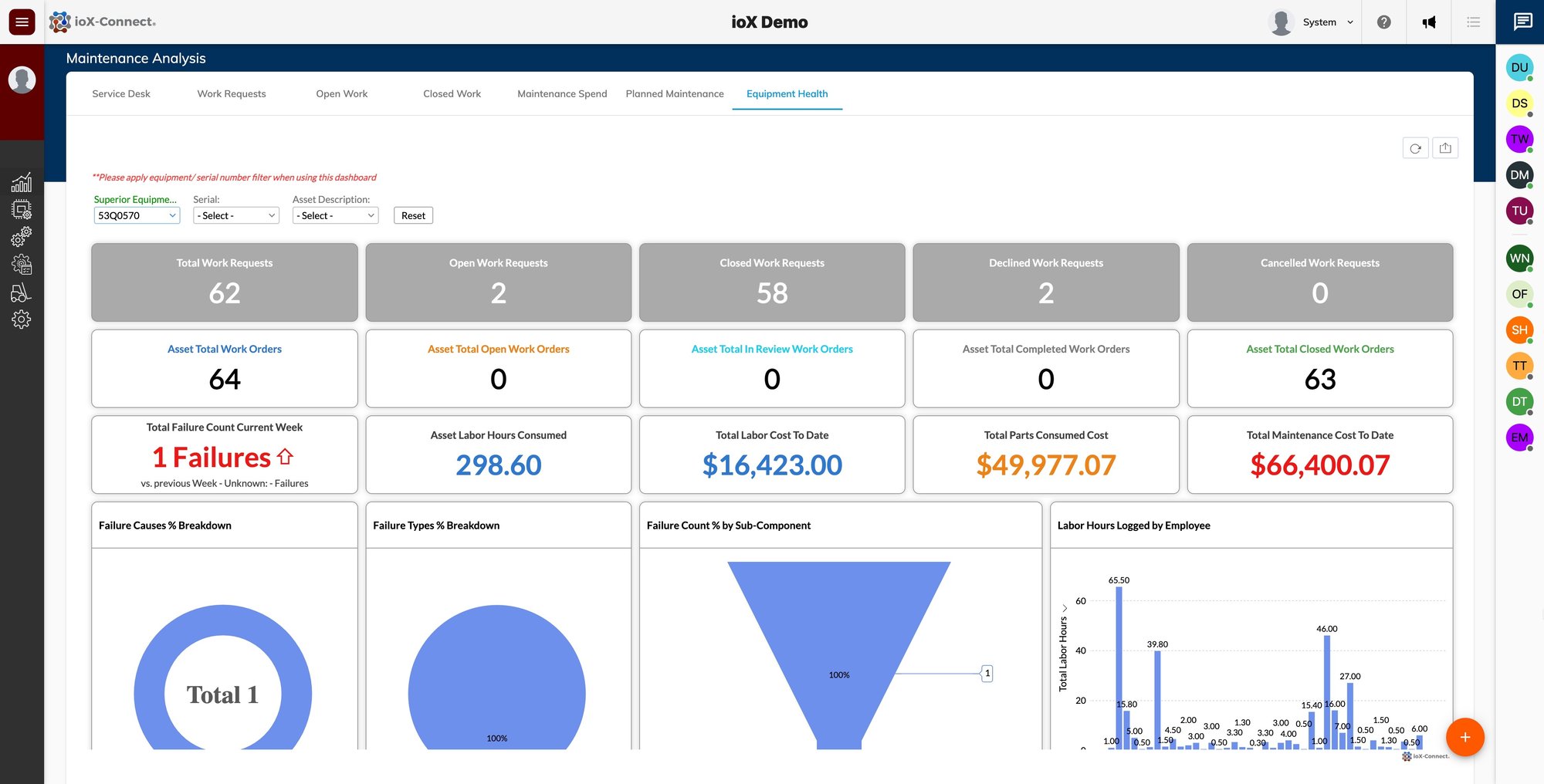

Real-Time Dashboards

Monitor your maintenance operations in real-time with intuitive dashboards. Visualize key performance indicators (KPIs) at a glance to stay informed and proactive.

- View live data on work orders, assets, and inventory.

- Customize dashboards to display the metrics that matter most.

- Identify issues quickly with visual indicators and alerts.

Performance Analytics

Evaluate the effectiveness of your maintenance program with detailed performance analytics. Track metrics such as mean time to repair (MTTR), mean time between failures (MTBF), and more.

- Analyze maintenance efficiency and asset performance.

- Identify trends and areas for improvement.

- Benchmark performance against industry standards.

Asset Lifecycle Tracking

Gain full visibility into the lifecycle of your assets. Track asset history, maintenance costs, and performance to make informed decisions about repairs, replacements, and investments.

- Monitor asset health and performance over time.

- Track maintenance costs to optimize asset lifecycle.

- Plan for asset replacements and upgrades with confidence.

Inventory Usage Reports

Stay on top of your inventory with detailed usage reports. Track which parts are being used, when, and where to optimize inventory levels and reduce waste.

- Monitor parts usage across work orders and sites.

- Identify frequently used items and potential shortages.

- Improve inventory planning and cost control.

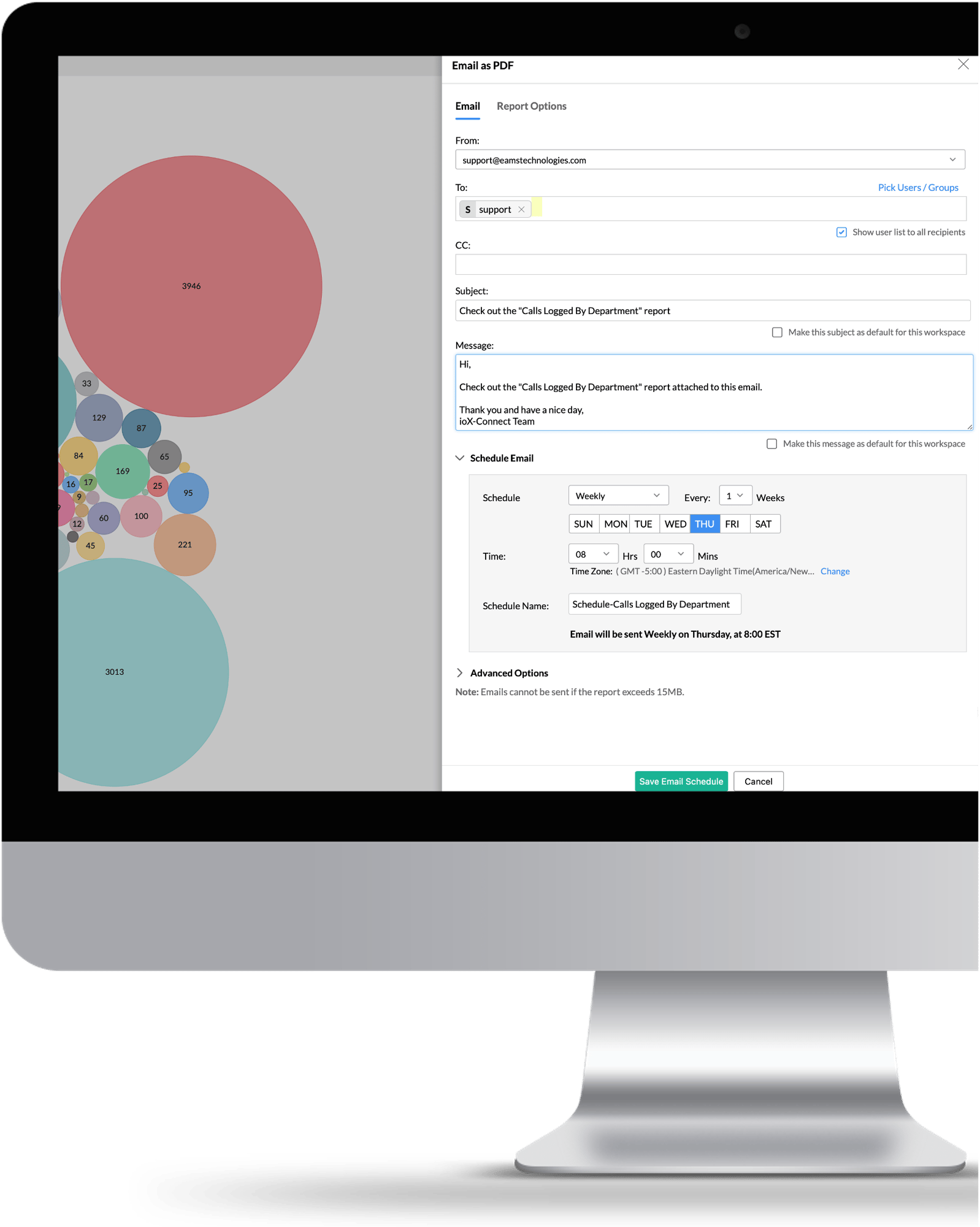

Scheduled Reports and Alerts

Automate report delivery and stay informed with scheduled reports and alerts. Ensure the right people get the right data at the right time.

- Schedule reports to be generated and sent automatically.

- Set up alerts for critical maintenance events or thresholds.

- Keep your team informed without manual effort.

Major Fracking Company

VP Maintenance Management

"ioX-CMMS is a game-changer in the maintenance management industry. It has helped us reduce equipment downtime and optimize our manpower. Highly recommended!"

Pharmaceutical Manufacturer

Engineering Manager

"ioX-CMMS is a top-performing maintenance management solution in the market. Its innovative tools and exceptional service make it a must-have for any business."

Connected

Designed specifically for IoT and mobile applications. Integrates with sensors, meters, PLCs, SCADA, ERP, MES, and nearly all corporate systems and solutions.

Fast

ioX-CMMS is quick to implement and use, with tools enabling setup in days and work orders in hours or seconds.

Smart

Our Dashboards and Analytics excel, offering standard options for basic needs and Custom Analytics for complex requirements.

Mobile

Our iOS app enables field technicians to manage work tasks and record job details effortlessly, designed for ease of use even for beginners.

AI-driven Recommendations from Vibration Sensor Data

What AI-driven recommendations can be provided based on vibrations sensor data?

Take your maintenance program to the next level with intelligent insights powered by AI. By leveraging vibration data from the ioX Advanced Vibration Sensor and other leading sensors, ioX-CMMS can identify early warning signs of equipment anomalies and provide data-driven recommendations.

- Receive instant notifications if sensor readings indicate potential faults or abnormal vibrations.

- Access actionable recommendations for corrective actions—such as lubrication, alignment, or component replacement—based on AI analysis of vibration trends.

- Reduce guesswork and manual diagnostics with automated root cause suggestions, allowing your team to address issues before they escalate.

- Transform your preventive maintenance strategy into a predictive one by using sensor-driven analytics to optimize uptime, cut costs, and improve equipment reliability.

Trusted by customers across multiple industries

Frequently Asked Questions About CMMS

Have more questions about how a CMMS can transform your maintenance operations? We’re here to help! Explore our FAQs for quick answers to common questions, or feel free to reach out to our team for personalized assistance. Let us guide you toward the right solution for your business needs.

Automating work orders by leveraging asset data offers numerous benefits that can transform how maintenance teams operate.

1. Immediate Response to Faults:

Automatically triggering work orders when asset data shows signs of a problem allows for swift interventions. This rapid response is crucial for preventing minor issues from escalating into major failures.

2. Data-Driven Decisions:

By analyzing sensor data, such as vibrations, automated systems can recommend corrective actions with precision. This data-driven approach empowers maintenance teams to make informed decisions, enhancing the quality of repairs and adjustments.

3. Enhanced Predictive Maintenance:

Evolving from traditional maintenance plans to a predictive model significantly boosts asset uptime. By foreseeing potential failures before they occur, you can schedule maintenance at the most opportune moments, reducing unplanned downtime.

4. Cost Efficiency:

Cost reduction is a significant advantage, as predictive maintenance minimizes unnecessary repairs and extends equipment life. The ability to focus resources on actual problem areas leads to more efficient spending.

5. Time-Saving Operations:

With automated systems handling initial diagnostics and work order creation, maintenance teams save valuable time. This efficiency allows them to concentrate on critical tasks rather than administrative work.

6. Increased Equipment Longevity:

Regular monitoring and timely interventions ensure assets remain in peak condition for longer periods, reducing the frequency of replacements and capital expenditures.

By capitalizing on real-time data insights and automating work orders, companies turn unpredictable maintenance needs into a streamlined, proactive strategy that saves time, cuts costs, and maximizes equipment uptime.

Boosting work order completion while reducing labor costs is a challenge many businesses face. However, achieving this goal is entirely possible by integrating dynamic strategies and leveraging technology. Here's how to get started:

1. Utilize Real-Time Tracking Systems

Implement technology that allows you to monitor the status of work orders with ease. Tools like ioX-CMMS provide dashboards for real-time updates, enabling you to have a comprehensive view of your operations at any moment. This facilitates quick decision-making and efficient management of resources.

2. Analyze Work Order Metrics

Focus on understanding critical metrics such as completion rates, wrench time, and total work hours. By regularly reviewing these data points, you gain insights into your workforce's efficiency and can identify areas ripe for improvement. Solutions like ioX-CMMS that offer robust reporting capabilities will be crucial to uncover these insights.

3. Optimize Scheduling and Resource Allocation

Ensure that your scheduling is optimized to reduce downtime and overlap among your workforce. Assign tasks based on skill and availability, thereby maximizing productivity and minimizing idle time.

4. Empower Your Technicians

Regular training and skill upgrades for your technicians can lead to greater efficiency. Encouraging feedback and involving them in process improvements can also enhance their performance and job satisfaction, leading to a higher quality of work.

5. Leverage Historical Data for Continuous Improvement

Employ software that uses historical data to forecast demand and workload, allowing you to predict peak periods and prepare accordingly. Platforms like ioX-CMMS can help you plan more effectively, thus reducing unnecessary labor costs and improving completion rates.

By implementing these strategies, you can boost work order completion rates as well as effectively manage and reduce labor expenses, leading to a more streamlined and efficient operation.

Integrating IIoT sensors and SCADA systems provides a powerful boost to asset monitoring by enabling comprehensive and real-time data accessibility. Here's how this integration enhances asset efficiency and reliability:

-

Real-Time Data Collection: IIoT sensors continuously capture vital metrics like temperature, pressure, vibration, and energy consumption. This constant stream of information helps in maintaining optimal asset performance by identifying abnormalities immediately.

-

Informed Decision Making: Access to historical data becomes straightforward with SCADA systems. Managers can review past performance trends, facilitating smart decision-making on maintenance schedules and resource allocation.

-

Automated Alerts and Analysis: Advanced integrations allow for setting custom alarms and parameters. This ensures that anomalies are flagged instantly, reducing downtime and preventing escalating failures. The capability to perform in-depth analyses, such as Frequency Domain (FFT) spectrum analysis, aids in diagnosing potential issues before they become critical.

-

Centralized Data Access: ioX-Connect allows for centralization of disparate data sources like SCADA and other control systems like PLC and BMS/BAS. This unified approach eliminates the problem of siloed data, offering a holistic view of asset utilization and operational efficiency.

-

Enhanced Operational Insights: With insights gathered from MES/MOM systems and aggregating data within solutions like ioX-CMMS, companies can better understand asset usage and performance, leading to improved process automation and productivity.

By harnessing these technologies, businesses achieve not only improved asset monitoring but also increased operational uptime and efficiency.

Our expert in-house team will assist you with effortlessly connecting ioX-CMMS with leading ERP platforms such as SAP, Microsoft NAV and NetSuite to streamline your parts requisition and purchasing workflows. With robust integrations in place, work order and inventory data flow directly between systems, eliminating manual data entry and reducing the risk of errors.

- Automatically generate purchase requests and orders for needed parts.

- Sync inventory levels across maintenance and procurement teams in real time.

- Reduce approval bottlenecks and accelerate parts delivery for critical repairs.

This seamless connectivity empowers your organization to keep inventory aligned, control costs, and ensure maintenance teams have what they need—when they need it.

Incorporating a robust platform like ioX-CMMS or ioX-Connect for generating enterprise-level reports offers numerous advantages that streamline and enhance operational efficiency. Here’s how such a solution can benefit your organization:

1. Effortless Report Creation

Gone are the days of struggling with complex data analysis. A user-friendly system allows for the easy creation of comprehensive reports, saving you from lengthy manual processes. With ioX-CMMS or ioX-Analytics, you can quickly compile and customize reports to meet the specific needs of your enterprise.

2. Simplified Operations Management

A good reporting platform like ioX-CMMS doesn't just generate reports—it simplifies your entire operations management. By providing clear, actionable insights, ioX-CMMS enhances maintenance and reliability reporting, enabling you to make informed decisions that enhance your business operations.

3. Quick Access to Key Performance Indicators (KPIs)

Stay on top of essential metrics like uptime and Overall Equipment Effectiveness (OEE) without hassle. Keeping track of these KPIs is crucial for monitoring asset performance and ensuring optimal operations, and ioX-CMMS provides instant visibility into these critical areas.

4. Time-Saving Templates and Automation

Say goodbye to repetitive tasks with pre-designed templates and automated report generation. This feature not only cuts down on the time spent compiling data but also ensures consistency and accuracy in your reporting.

5. Enhanced Collaboration and Support

ioX-CMMS offers strong MRO (Maintenance, Repair, and Operations) reporting capabilities and we can provide guidance and support in this area. ioX-CMMS's collaborative environment fosters continuous improvement and ensures you're maximizing the platform's potential.

By leveraging these benefits, your organization can achieve greater efficiency, improve decision-making, and focus on strategic growth rather than getting bogged down by data complexities.

Condition monitoring is a powerful tool in the fight against unexpected machine failures.

Here's how it can help:

-

Deep Insights into Performance: By employing condition monitoring, you gain access to comprehensive dashboards that detail the health of your machinery. They provide real-time data on critical metrics such as vibration, temperature, and pressure.

-

Early Failure Prediction: One of the standout benefits of ioX-CMMS is the ability to predict potential failures before they occur. Monitoring trends and anomalies over time allows you to identify the signs of imminent issues, giving you a chance to address them proactively.

-

Prolonged Asset Lifespan: With regular monitoring, you can optimize maintenance schedules, which in turn extends the lifespan of your equipment. By understanding wear patterns and failure points, maintenance can be executed more efficiently.

-

Efficient Resource Allocation: Knowing which machines are at risk enables better resource planning and allocation. This foresight minimizes downtime and ensures that maintenance efforts are both timely and effectively targeted.

-

Data-Driven Decisions: The detailed analysis available in ioX-CMMS from condition monitoring supports more informed decision-making. With data at your fingertips, you can better plan for replacements, upgrades, and preventive measures.

By integrating ioX-Connect sensors for condition monitoring into your maintenance strategy, you not only prevent failures but also enhance the overall efficiency and longevity of your machinery.

Global Vision and Standardization

Managing a global, multi-site operation demands seamless communication and standardization. With enterprise reporting tools found in ioX-CMMS, you gain comprehensive visibility across locations, enabling you to establish and replicate successful maintenance strategies worldwide.

Streamlined Data Reporting

Effective enterprise asset management (EAM) hinges on consistent data representation. ioX-CMMS harmonizes maintenance data across different sites, allowing for intuitive report generation that incorporates global metrics. This simplifies the identification of cost-saving opportunities and optimizes operational efficiency.

Cross-Site Strategy Implementation

A true multi-site Computerized Maintenance Management System (CMMS) like ioX-CMMS transcends geographical and cultural barriers. Generate reports that align work sites despite differences in languages, currencies, and measurement standards. This allows for the application of industry best practices through uniform workflows and procedures, driving performance improvements in key performance indicators (KPIs) across your organization.

Audit-Ready and Compliance Assured

Stay audit-ready with dedicated dashboards that streamline the demonstration of compliance. Present your clear-cut work order processes, verified by quality personnel or supervisors, and provide auditors with precise, timestamped user actions and modifications.

ioX-CMMS provides, enterprise and multi-site reporting tools that are essential for businesses aiming to harness the power of global data, maintain compliance with ease, and drive cross-location success with standardized strategies.

If you're looking for assistance with your reporting and analytics, you're in luck. Our dedicated team of experts is always on hand to guide you through creating insightful reports and interactive dashboards. Here’s how we ensure you get the most out of your data:

-

Expert Design Assistance: Our professionals can craft tailored reports and dashboards that deliver instant clarity on your maintenance activities and key performance indicators (KPIs).

-

Imbed Your Own Dashboard: Prefer to use your own dashboards? ioX-CMMS has the necessary features to provide you direct data base access to your data for building reports and dashboards outside of our system. You can then imbed those dashboards from example PowerBI directly into your ioX-CMMS solution.

-

24/7 Support Availability: No matter when you need help, our support services are available around the clock to ensure you have a seamless experience.

With these support options, you can transform your data into actionable insights with ease and confidence.

You can save your reports, tables, and graphs in several different formats to fit your needs. Choose from detailed Excel spreadsheets (XLSX), easy-to-read PDFs, or image files for quick sharing. With these options, you'll have flexibility in how you view and distribute your data, ensuring compatibility across most devices and platforms. ioX-CMMS can also provide you with a secure link to any dashboard or report if you want to share data insights to users outside of the ioX-CMMS solution.

A Computerized Maintenance Management System (CMMS) is software that helps organizations manage and streamline maintenance operations. It tracks work orders, schedules preventive maintenance, monitors assets, and provides analytics to improve efficiency and reduce downtime. For a more in depth look at what is a CMMS, check out our What is a CMMS Informational Page

A CMMS centralizes maintenance data, allowing users to create work orders, schedule tasks, track asset performance, and access real-time insights. Technicians can update task statuses, log maintenance activities, and access manuals or checklists, ensuring smooth operations.

A CMMS improves maintenance efficiency, reduces unplanned downtime, extends asset lifecycles, and enhances compliance. It also provides data-driven insights for better decision-making and streamlines communication between teams.

CMMS software is used by maintenance managers, technicians, and facility managers across industries such as manufacturing, healthcare, hospitality, utilities, and logistics to manage equipment and facilities effectively.

While both systems manage assets, a CMMS focuses on maintenance operations, such as work orders and preventive maintenance. Enterprise Asset Management (EAM) provides broader asset lifecycle management, including procurement, inventory, and financials.

Yes, a CMMS like ioX-CMMS supports multi-site management, allowing users to track assets, work orders, and maintenance schedules across multiple facilities from a single platform, ensuring data segregation and efficient management.

A CMMS automates preventive maintenance scheduling based on time, usage, or condition triggers. This ensures timely inspections and repairs, reducing breakdowns and extending equipment lifespans.

Modern CMMS platforms, like ioX-CMMS, are designed with an intuitive interface, making them easy to use for technicians and managers alike. Mobile accessibility further enhances usability, allowing updates from anywhere.

A CMMS provides detailed reports on work order history, asset performance, maintenance costs, technician productivity, and compliance metrics. These insights help optimize maintenance strategies and improve ROI.

To choose the best CMMS, consider your organization's size, industry, and specific needs. Look for features like work order management, preventive maintenance, multi-site support, mobile access, and robust reporting. A scalable and customizable solution like ioX-CMMS is ideal for businesses of all sizes.

Our Products and Services?

We're here to help, do not hesitate to reach out to us by scheduling a quick call with one of our representatives.

Contact Us

Our customer service team is ready to assist you in exploring our offerings tailored to your business objectives.